rockwell hardness test viva questions|rockwell hardness test theory : convenience store Testing of Materials Questions and Answers – Rockwell Hardness Test. This set of Testing of Materials Multiple Choice Questions & Answers (MCQs) focuses on “Rockwell Hardness . Resultado da Chevrolet Onix LT2 1.0 Manual. Preço normal R$ 68.900,00 Preço promocional R$ 68.300,00 R$ 68.900,00 Preço promocional R$ 68.300,00

{plog:ftitle_list}

Resultado da Goldberg Lan Steam Emu v0.2.4 released. The latest Goldberg Emulator has been released on gitlab . Released under the GNU LGPLv3, this is a .

Testing of Materials Questions and Answers – Rockwell Hardness Test. This set of Testing of Materials Multiple Choice Questions & Answers (MCQs) focuses on “Rockwell Hardness .

This set of Engineering Materials & Metallurgy Multiple Choice Questions & .

VII. VIVA QUESTIONS: 1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness .

In Rockwell hardness experiment, the value obtained is 45HRB. What is the letter B indicates

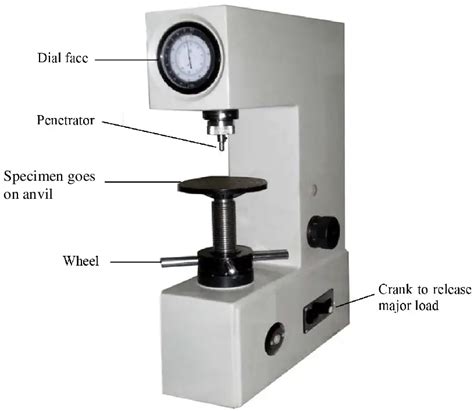

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .

Why minor load is initially applied in Rockwell hardness test? a: specimen cannot bear the major load. b: to distribute the load acting on the specimen. c: to firmly seat the penetrator in to .What minimizes the amount of surface preparation in Rockwell test? Hardened steel is tested on the C scale with ________ indenter and a _______ kg major load.Because of its simplicity, accuracy & extremes versatility, the Rockwell hardness test is more widely used than any other hardness test. It permits measurement of wide range of hardness .This set of Engineering Materials & Metallurgy Multiple Choice Questions & Answers (MCQs) focuses on “Hardness Tests on Metals”. 1. What kind of indenter is used in a Brinell test? a) .

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell .A hardness test can be conducted on Brinell testing m/c, Rockwell hardness m/c or vicker testing m/c. the specimen may be a cylinder, cube, think or thin metallic sheet.A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .

This article explains the procedure to perform the Rockwell hardness test on metals. Rockwell Hardness Test Procedure. The Rockwell hardness test employs the principle of differential-depth method. During the test, the .A Brinell-cum-Rockwell hardness testing m/c along with the specimen is shown in figure. Its specification are as follows: 1. Ability to determine hardness upto 500BHN. 2. Diameter of ball (as indentor) used D = 2.5mm, 5mm, 10mm. . VIVA-QUESTIONS:- • What is the limitation of Brinell hardness test and why ?A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

concrete hardness testing equipment

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

Description:-Hardness may be defined as resistance of metal to plastic deformation usually by indentation.However the term may also refer to stiffness or temper or resistance to scratch, abrasion or cutting. There are three general types of hardness measurements depending upon the manner in which the test is conducted.The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

rockwell hardness testing questions

Double Shear Test 29 VIVA-VOCE QUESTIONS 31 . 1. ROCKWELL HARDNESS TESTS Aim: To determine the Rockwell hardness number on B and C scales for a given metallic specimen. Test Setup: Rockwell Hardness Testing Machine. Indenters: i) For Rockwell – B Test: Steel ball indenter of diameter (1/16)th inch. ii) For Rockwell . Aerospace Materials and Processes Multiple Choice Questions on “Aircraft Materials – Hardness testing – Brinell and Rockwell Hardness”. 1. Which of the following is not a hardness testing method? a) Rockwell hardness b) Brinell hardness c) Set method hardness d) Shore scleroscope hardness Answer: c ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

This test is commonly also called the diamond-pyramid hardness test. 4. What is the angle of indenter in Vicker’s hardness test? a) 96 degrees b) 110 degrees c) 136 degrees d) 150 degrees View AnswerAnswer: c Explanation: In Vicker’s hardness test, a square pyramid-shaped indenter is used for indentation.The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .Viva Voce Questions. Strength of materials Lab. 1. Define Hooke’s Law. 2. Define Strength of materials . Enumerate the advantages of Rockwell Hardness test over Brinell hardness test. 62. Differentiate between pneumatic and hydraulic pumps. 63. Unit of force, deflection, stress, strain, E, K, G. .In C-scale of Rockwell hardness testing, the shape of indenter used is a: Diamond cone Explanation. Explanation. b: Steel ball Explanation. Explanation. c: Steel prism Explanation. Explanation. d: Any of the above Explanation. Explanation. Submit Quiz .

Hardness. Hardness is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. Rockwell hardness test. Rockwell hardness testing is a general method for measuring the bulk hardness of metallic and polymer materials. Rockwell hardness testing is an indentation testing method. Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. Rockwell invented the Rockwell hardness test. As a metallurgist for a large ball bearing company, he wanted a fast, nondestructive .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read the standard completely before . The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.Material Testing Lab Online Viva quiz for Professional Development. Find other quizzes for Professional Development and more on Quizizz for free! . 15 questions. Copy & Edit. Save 15 questions . In Rockwell hardness experiment, the value obtained is 45HRB. What is the letter B indicates. Brass. Brown specimen. B Scale. Medium hardness. 4 .

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

The RockGen Rockwell Hardness Testing System was designed to test the hardness level of metal based on the indentation they leave on a tested material according to the Rockwell scale. The machine is capable of measuring the resolution of a material to a 0.001″.

The Rockwell hardness test involves indenting the surface of a material with a diamond cone or steel ball indenter and measuring the depth of the resulting indentation. Significance of Rockwell Hardness. Rockwell hardness is significant because it is a quick and easy method of measuring the hardness of a material. It is also a reliable method .

rockwell hardness testing machine

rockwell hardness tester

web14 linhas · Escolha um modelo pelo nome ou pelo código FIPE para ver o valor médio de mercado da Tabela FIPE HB20 para cada ano. Depois pode também consultar o gráfico de desvalorização do modelo escolhido ou escolher outro modelo. A Tabela FIPE de .

rockwell hardness test viva questions|rockwell hardness test theory